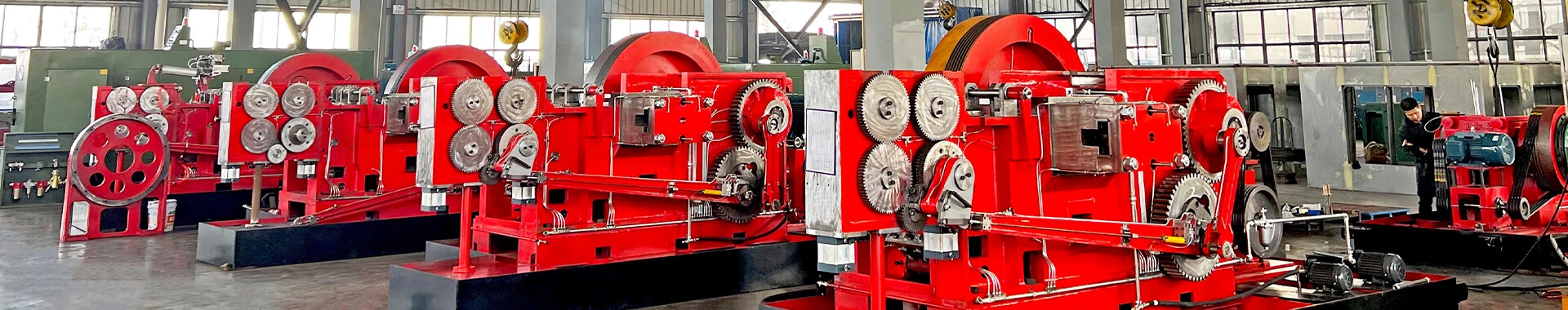

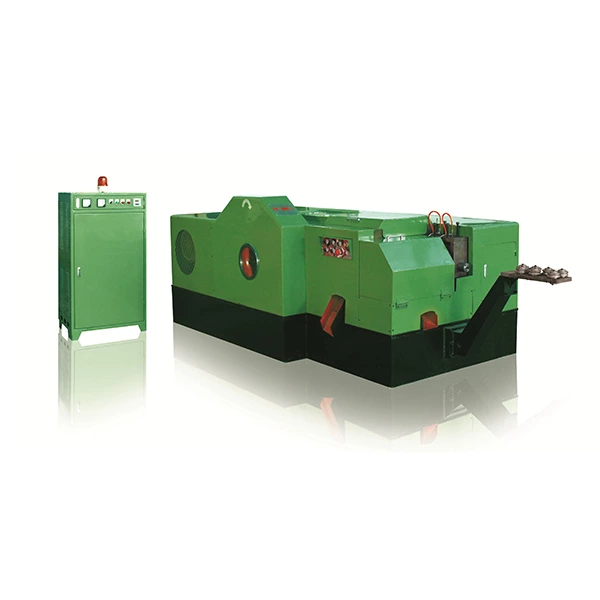

Six station and seven station nut forming machine are available, both standard machine and Extended Nut Forming Machine. The equipment has good stability, long service life and high production efficiency. Machine can make various nuts such as: Normal hex nuts, Extra thick nut, Flanged nut, Motorcycle link pin, Oil Plug screw, Hex socket lockup nut, Square nut, Weld nut, Cap nut, Blind Nut, Chain roller, Expansion anchor, Bicycle and Motorcycle Spare Parts, Some rivets, Non-standard fastener, etc. We also offer customization service according to user product requirements.

Standard Type Nut Former Technical Parameters

| MODEL | ZF08B | ZF11B | ZF14B | ZF14B | ZF17B | ZF19B | ZF24B | ZF27B | ZF30B | ZF33B | ZF36B | ZF41B | |

| FORGING STATION | 6S | 6S | 6S | 6SL | 6S | 6S | 6S | 6S | 6S | 6S | 6S | 6S | |

| CUTOFF DIA(MM) | 8 | 12 | 15 | 15 | 18 | 20 | 25 | 28 | 30 | 34 | 36 | 40 | |

| CUTOFF LENGTH(MM) | 10 | 20 | 25 | 28 | 30 | 30 | 25 | 40 | 40 | 45 | 45 | 50 | |

| KNOCK-OUT LENGTH(MM) | 12 | 25 | 45 | 45 | 45 | 75 | 95 | 95 | 95 | 105 | 105 | 120 | |

| CENTER DISTANCE(MM) | 38 | 50 | 60 | 60 | 70 | 80 | 100 | 115 | 120 | 140 | 150 | 165 | |

| PRODUCT SIZE(MM) | 3# 1/8 M2.5-M5 | 4# 1/4 M4-M6 | 1/4 3/8 M6-M8 | 1/4 3/8 M6-M8 | 1/4 7/16 M8-M10 | 5/16 9/16 M10-M12 | 3/8 5/8 M12-M18 | 3/8 3/4 M12-M18 | 1/2 3/4 M12-M20 | 1/2 7/8 M12-M22 | 5/8 1 M16-M24 | 3/4-9/8 M20*M27 | |

| RAM STROKE(MM) | 38 | 64 | 70 | 90 | 80 | 100 | 130 | 130 | 120 | 160 | 160 | 200 | |

| PRODUCTION SPEED(PCS) | 140-220 | 120-200 | 100-180 | 70-120 | 90-130 | 70-100 | 60-100 | 50-80 | 50-80 | 50-100 | 50-90 | 50-80 | |

| FORGING POWER(TOM) | 50 | 65 | 90 | 90 | 120 | 200 | 260 | 320 | 350 | 450 | 550 | 650 | |

| MAIN MOTOR(HP) | 10 | 15 | 30 | 30 | 40 | 50 | 75 | 100 | 100 | 150 | 200 | 250 | |

| APPROX.WT(TON) | 3 | 4.5 | 8.5 | 8.5 | 10.5 | 16 | 26 | 30 | 35 | 50 | 55 | 70 | |

| MACHINDIMENSIONS(M) | (L) | 1.9 | 2.6 | 2.8 | 2.8 | 3.4 | 4.3 | 4.7 | 5.4 | 5.3 | 6.5 | 6.8 | 7.2 |

| (W) | 1.3 | 1.5 | 2 | 2 | 2.1 | 2.3 | 2.9 | 2.6 | 2.7 | 3.2 | 3.5 | 3.8 | |

| (H) | 1 | 1.2 | 1.5 | 1.6 | 1.6 | 1.8 | 2 | 2.1 | 2.2 | 2.6 | 3 | 3.2 | |

Long Stroke Type Nut Former Technical Parameters

| MODEL | ZF11B | ZF11B | ZF11B | ZF14B | ZF14B | ZF14B | ZF17B | ZF19B | ZF19B | ZF22B | ZF22B | ZF24B | ZF24B | ZF27B | ZF30B | ZF33B | ZF36B | ZF41B | |

| FORGING STATION | 6SL | 6SLL | 7SLL | 6SLL | 6SLLL | 7SLL | 6SL | 6SL | 6SLL | 6SL | 6SLL | 6SL | 7SL | 6SL | 6SL | 6SL | 6SL | 6SL | |

| CUTOFF DIA(MM) | 12 | 12 | 12 | 16 | 16 | 16 | 18 | 20 | 20 | 20 | 20 | 25 | 25 | 28 | 30 | 34 | 36 | 42 | |

| CUTOFF LENGTH(MM) | 25 | 30 | 30 | 55 | 55 | 55 | 40 | 40 | 45 | 45 | 45 | 50 | 50 | 50 | 50 | 50 | 65 | 65 | |

| KNOCK-OUT LENGTH(MM) | 42.5 | 52.5 | 52.5 | 75 | 95 | 75 | 75 | 75 | 90 | 90 | 90 | 95 | 95 | 95 | 95 | 105 | 105 | 120 | |

| CENTER DISTANCE(MM) | 50 | 50 | 50 | 60 | 60 | 60 | 70 | 80 | 80 | 90 | 90 | 100 | 100 | 115 | 120 | 140 | 150 | 165 | |

| PRODUCT SIZE(MM) | Φ12 | Φ12 | Φ12 | Φ14 | Φ14 | Φ14 | Φ17 | Φ20 | Φ19 | Φ20 | Φ20 | Φ24 | Φ24 | Φ28 | Φ30 | Φ33 | Φ36 | Φ42 | |

| PRODUCT SIZE(MM) | 30mm | 40mm | 40mm | 60mm | 80mm | 60mm | 60mm | 60mm | 80mm | 60mm | 80mm | 80mm | 80mm | 80mm | 80mm | 90mm | 90mm | 90mm | |

| RAM STROKE(MM) | 100 | 140 | 140 | 220 | 240 | 180 | 180 | 180 | 220 | 180 | 220 | 230 | 230 | 230 | 120 | 280 | 280 | 300 | |

| PRODUCTION SPEED(PCS) | 80-160 | 80-120 | 80-120 | 70-90 | 50-70 | 70-90 | 70-90 | 60-90 | 60-90 | 60-90 | 60-90 | 60-90 | 60-90 | 60-80 | 50-80 | 60-80 | 50-75 | 50-75 | |

| FORGING POWER(TOM) | 65 | 80 | 80 | 90 | 90 | 90 | 120 | 200 | 200 | 200 | 200 | 260 | 260 | 320 | 350 | 450 | 550 | 650 | |

| MAIN MOTOR(HP) | 20 | 20 | 20 | 30 | 30 | 30 | 40 | 60 | 60 | 60 | 60 | 75 | 100 | 100 | 100 | 200 | 200 | 300 | |

| APPROX.WT(T) | 4 | 4.8 | 5 | 9 | 10 | 10 | 11 | 17 | 18 | 18 | 18 | 30 | 32 | 35 | 35 | 50 | 55 | 95 | |

| MACHINDIMENSIONS(M) | (L) | 2.6 | 2.8 | 2.8 | 3.5 | 3.6 | 3.5 | 3.7 | 4.7 | 4.8 | 4.7 | 4.8 | 5.3 | 5.3 | 5.4 | 5.6 | 6.5 | 7 | 7.5 |

| (W) | 1.5 | 1.6 | 1.6 | 2 | 2 | 2 | 2.1 | 2.3 | 2.3 | 2.3 | 2.3 | 2.9 | 2.9 | 2.6 | 2.7 | 3.2 | 3.8 | 4 | |

| (H) | 1.3 | 1.3 | 1.3 | 1.6 | 1.6 | 1.6 | 1.7 | 1.9 | 1.9 | 1.9 | 1.9 | 2 | 2 | 2.1 | 2.4 | 2.6 | 3 | 3.2 | |